Is it possible for a 3D printer to print itself? In the 3D printing sector, we are frequently asked this question. Isn’t it amazing if machines could self-replicate? It has the potential to open up new opportunities in numerous areas, from manufacturing to building, generate new sorts of supply chains and potentially reshape the planet through new spatial construction approaches. Is it viable to create a 3D printer in 3D? Let’s see.

Is it possible to manufacture a 3D printer in 3D?

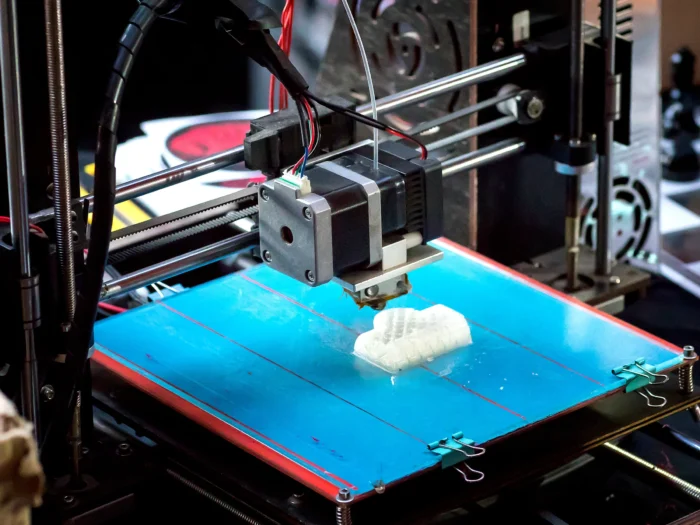

Yes, a 3D printer can be printed in 3D! Self-replicating 3D printers have been developed, and several versions have already been released. These 3D printers are unable to complete the entire task. Each component must be 3D printed separately and then assembled. In addition, some pieces cannot be 3D printed as electronic components. So, you can 3D print a 3D printer, but not entirely.

This also applies to only plastic 3D printing. Other types of 3D printers, such as metal, liquid resin, and ceramic 3D printers, cannot be manufactured in this manner.

What is the mechanism of the 3D printer?

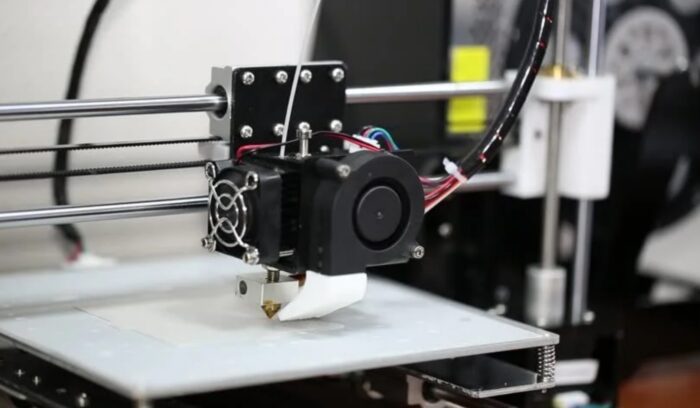

The manufacturing procedure is the same as any other 3D-printed object. The parts are available online; however, making alterations may require 3D modeling or CAD software. The process of 3D printing your pieces layer by layer would be repeated. Material extrusion should proceed smoothly and generate thin layers. You should also consider the surface smoothness, which will not be the finest due to FDM technology.

Why should you develop a 3D printer that is printed in 3D?

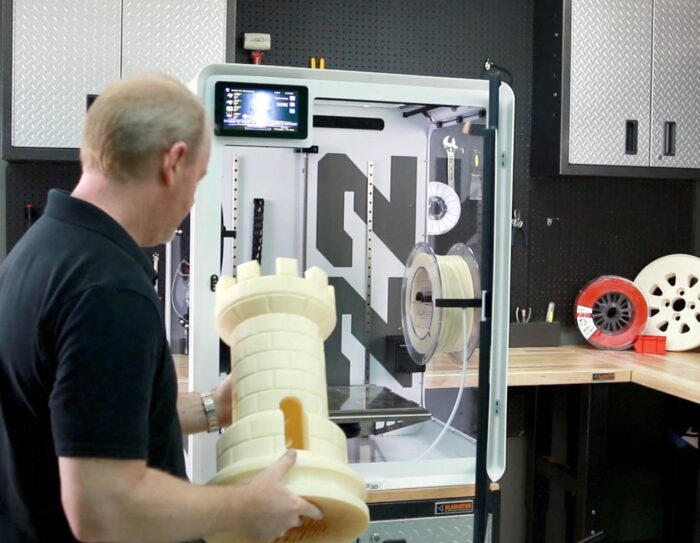

Making your personal 3D printer can provide you with many opportunities to learn. It enables you to thoroughly understand the project and delve into the 3D printing mysteries. You will not only obtain a wealth of knowledge, but you will also become an expert in the event of any repairs.

You have new design freedom with 3D printing. As a result, you can create and personalize your 3D printer to meet your specific requirements. No other technology allows you to create a fully configurable machine to make parts.

The First Self-Replicating 3D Printer, RepRap

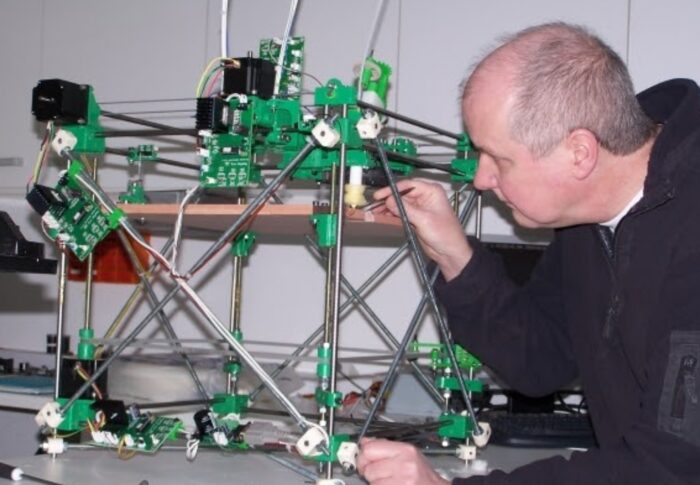

Dr. Adrian Bowyer, senior lecturer in the Department of Mechanical Engineering at the University of Bath, designed the first self-replicating 3D printer through the RepRap project, which he started in 2005. In 2008, he unveiled his first working machine, the RepRap “Darwin,” which contained 50% self-replicated parts.

The RepRap project’s 3D printers use Fused Deposition Modeling (FDM) printing technology and plastic 3D printing materials. They are desktop 3D printers; hence their uses are limited compared to industrial Additive Manufacturing.

They are also unable to print completely on their own. Because they are plastic 3D printers with plastic parts, they can 3D print some pieces as well as entirely create other 3D printed products. After that, you’ll have to put them together and add any components that can’t be 3D printed, such as electronics or metal bits (since it is a plastic 3D printer).

3D Printing a Printer: What You Need to Know

Following these few guidelines will assist you in creating a perfect 3D printing file and avoiding the most common problems that render your file unprintable. However, as an online business, we are well aware of the most typical blunders made by our customers, and we will explain how to prevent them today.

1. Select the most appropriate 3D modeling software.

It is critical to select 3D modeling software tailored to your demands and the specifics of your project. A curriculum suitable to your schemes and industry will give you the best possible start.

But how can you pick the best 3D modeling software? We all know that choosing the right 3D software isn’t easy. However, there are numerous programs on the market nowadays. If you work in architecture, chemistry, automotive, or medicine, you will undoubtedly need modeling software. It’s the only 3D modeling software that combines creative, technical, rendering, and 3D printing capabilities into one application! Anybody can handle it; no scientific knowledge is required. It is effortless to use. Adapted tools will save you time and help you construct the greatest 3D model possible.

A Magic Fix tool assures the model’s geometry is stable. An in-built slicer assists you in slicing your models and generating G-Code for your 3D printer.

It’s the most cost-effective professional 3D printing technology available, and both novices and experts utilize it. You can sign up for a free account and use it to test out the program before upgrading to the premium version if you like it.

2. Select project-specific material.

You may not want to employ the same materials or finish for a prototype and a completed product. Is it necessary to employ a rubber-like, slightly flexible substance or a hard, stress-resistant material? You need to choose the details according to your design requirements.

3. Follow the design rules as closely as possible.

Before you can complete the design of your future 3D printed creation, you must first choose the material used to construct the customized plan.

Find out the details regarding the design criteria for the material. All components are unique, with distinct qualities and limits, but they all follow precise design rules!

4. Make sure your files are in good working order.

You’ll need an excellent 3D model to receive a 3D printed object. If you are unfamiliar with 3D design for 3D printing, you may end up with a 3D file that contains too many flaws to be produced. As a result, before uploading your file to our online 3D printing service, you can use an STL editor like SelfCAD, Meshlab, or Netfabb to reorganize your model without difficulty.

Once your 3D file has been uploaded, you will be able to examine the issues in the viewer and make changes to your project immediately in your 3D modeling software. Some problems, such as reconstructions, can be automatically rectified using our repair mechanism; however, larger errors will require you to modify your file.

5. Remove your portion and hollow it out.

You can hollow out your part and remove all of the powder by drilling holes in it. This will have two effects: it will lower the cost of your purchase and reduce the weight of the 3D printed object because less material will be used.

6. Before starting the printing process, make sure your parts are solid.

We propose that you examine the solidity of your part before sending it to our 3D printer. Indeed, making a solid 3D model isn’t the only thing you’ll have to do. You also want your model to be 3D printable on our machines so that you can avoid iterations with our customer support and save time in the process.

This is why you must consider their constraints, such as the minimum object width. To avoid any potential dangers, make sure that none of your design’s minor parts is less than 2mm in diameter since they would easily break while being prepared for you. Again, to avoid any of these issues, follow the design guidelines.

7. Keep your part’s orientation in mind.

The surface of your part can be affected by its orientation in the 3D printer. The direction of the region will be determined by its final application. The section may have a “staircase effect” from certain angles, which is undesirable if it is a visible feature of your project.

What are the capabilities of a 3D printer?

Designers, engineers, and anybody interested in developing a project and seeking benefits such as creativity, adaptability, and scalability at a reasonable cost can employ additive manufacturing.

3D printers offer multiple possibilities for production or rapid prototyping in various industries, including automotive, fashion, medical, and entertainment. The list of products that could be 3D printed appears to be unlimited, including props, jewelry, tools, replacement parts, and prosthetics.

The most demanding sectors can now start utilizing additive manufacturing because of varied elements and the development of high-performance components.

What are some of the benefits of 3D printing?

If you’re interested in learning more about 3D printers and how they work, you’ll need to know about their benefits. The following are the key advantages of additive manufacturing:

Flexibility

Your business will have more flexibility thanks to 3D printing. You may simply 3D print a part when you need it. You can also modify it. You may order as many features as you need using an online 3D printing service; there is no minimum order quantity; from 1 to 10K+ components, you only print what you need, on-demand.

Quick Iteration

Additive manufacturing is a terrific option if you need to get a product to market quickly. You’ll be able to manage iterations more effectively and efficiently. When it comes to running a business and producing initiatives, time is money. A vital component of your business is saving time and speeding up the entire product development cycle.

Innovation

You can duplicate all of your ideas to turn them into tangible objects. It is possible to print even the most intricate shapes. You will be liberated from the constraints of traditional manufacturing when you use 3D printing. Designing for a layer-by-layer method like 3D printing is also different: a 3D design made for injection molding will not be converted for 3D printing.

Customization

Mass-customization can benefit several industries, ranging from medicine to consumer goods manufacturing and automobiles. For example, in the medical field, additive manufacturing allows for the development of custom prostheses and devices. It may even be employed to make customized 3D printed eyewear.

The supply chain can be improved

Implementing additive manufacturing in your process is also a great way to rethink your supply chain and consider dematerializing your storage. You don’t have to store your parts with 3D printing; instead, you can produce them as needed. This cutting-edge technique is ideal for low-volume printing. It may be more cost-effective than other manufacturing methods.

Conclusion

In this article, we learn about 3D printing a printer. The manufacturing procedure for a 3D printer is the same as any other 3D-printed object. For 3D modeling, we require CAD software.