In today’s fast-paced and technology-driven world, Electrostatic Discharge (ESD) has become a major concern in various industries, including electronics manufacturing, telecommunications, aerospace, and medical equipment production. ESD can cause irreparable damage to sensitive electronic components and assemblies, resulting in costly repairs, product defects, and even safety hazards. To prevent these issues, ESD goods such as ESD foam play a critical role. But, not all ESD foam suppliers are created equal. Choosing the right ESD foam supplier is of paramount importance for ensuring the effectiveness of your protection measures.

ESD: A Growing Concern

Electrostatic Discharge, or ESD, occurs when an imbalance of electric charge is discharged between two objects with different electrical potentials. This discharge can generate voltages high enough to damage or disrupt the operation of electronic components and assemblies. ESD-related problems can range from minor inconveniences to catastrophic failures. As electronic devices become smaller, more complex, and more sensitive, the risk of damage continues to grow. Thus, companies need to invest in ESD protective measures, and foam is a key component in this regard.

ESD Foam: A Shield Against Electrostatic Discharge

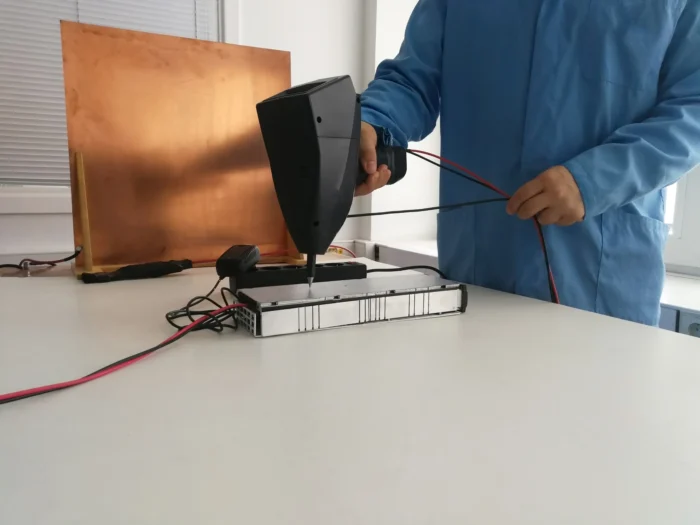

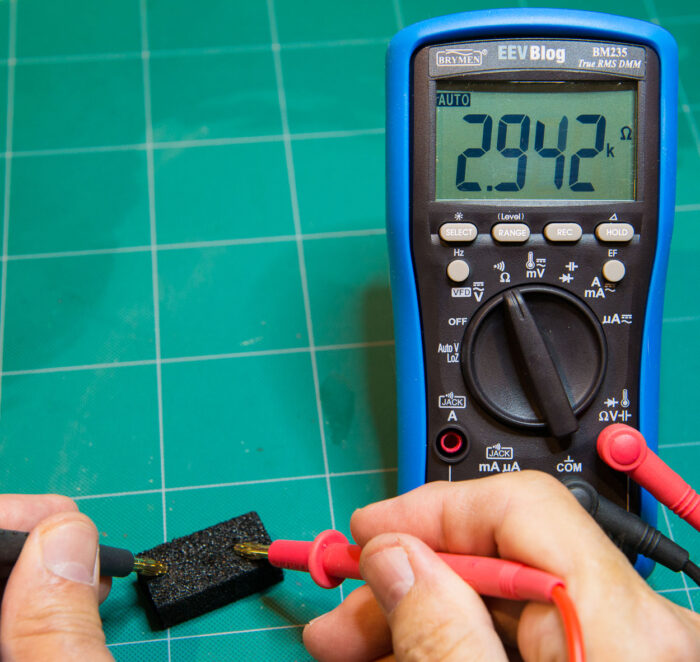

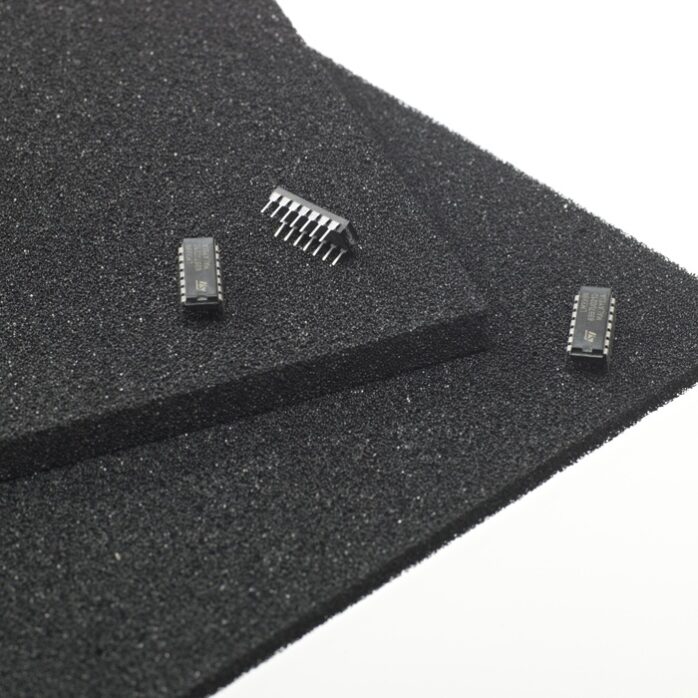

ESD foam is a specialized material that helps protect sensitive electronic components and devices from ESD damage. It does so by providing a conductive path for electrostatic charges to safely dissipate. This prevents the accumulation of static charges on the surface of components, reducing the risk of discharge. foam is commonly used in the packaging and transportation of electronic components and assemblies to ensure they remain ESD-safe throughout their lifecycle. However, not all foam is created equal, and the quality of ESD foam can significantly impact its effectiveness. Choosing the right ESD foam supplier is, therefore, crucial.

Key Factors to Choose an ESD Foam Supplier

When it comes to choosing an foam supplier, there are several key factors to consider. Making the right choice can save your business time, money, and headaches down the road. Here are some of the most critical factors to keep in mind:

-

Quality and Certification

Quality is paramount when it comes to protection. Your chosen foam supplier should provide high-quality foam products that meet or exceed industry standards. Look for suppliers that have certifications or compliance with industry standards like ANSI/ESD S20.20, ISO 9001, or other relevant quality management systems. Certification ensures that the supplier’s products have undergone rigorous testing and meet the requirements for ESD protection.

-

Range of Products

ESD protection requirements can vary depending on the application. Therefore, it’s essential to choose a supplier that offers a wide range of foam products. Whether you need foam for packaging, workstation surfaces, or custom-cut solutions, a supplier with a diverse product catalog can accommodate your specific needs.

-

Customization Options

Every protection scenario is unique, and off-the-shelf solutions may not always suffice. A reputable foam supplier should be willing and capable of providing customized solutions to meet your specific requirements. This may include custom foam dimensions, shapes, or even printing with your company’s logo or warnings.

-

Technical Expertise

Choosing an ESD foam supplier with a team of experts is advantageous. They can offer valuable advice on selecting the right materials and designs to ensure the most effective ESD protection for your application. Technical expertise can also help in troubleshooting and resolving any ESD-related issues that may arise.

-

Consistent Supply and Delivery

Reliable and consistent supply is crucial for businesses that depend on foam to protect their products and operations. The right supplier should have robust supply chain management and offer dependable delivery options to ensure you always have access to the foam products you need.

-

Cost-Effective Solutions

While quality is vital, cost is a factor that cannot be ignored. Look for a supplier that offers competitive pricing without compromising quality. Long-term partnerships with suppliers can often lead to cost-saving opportunities, so it’s wise to choose a supplier with whom you can establish a stable and mutually beneficial relationship.

-

Customer Support

Exceptional customer support is crucial when dealing with protection. Your chosen supplier should be responsive to your queries, provide technical assistance when needed, and offer efficient customer service throughout the procurement process and beyond.

-

Environmental Responsibility

Environmental considerations are increasingly important in today’s business landscape. Choosing an foam supplier that demonstrates a commitment to environmental responsibility, such as recycling or using sustainable materials, can align with your company’s values and goals.

Consequences of Choosing the Wrong ESD Foam Supplier

Choosing the wrong foam supplier can have significant consequences for your business. These consequences may include:

- ESD-Related Failures: Low-quality foam may not provide adequate protection, resulting in damage to electronic components and assemblies. This can lead to costly product failures and warranty claims.

- Compliance Issues: Using foam that does not meet industry standards or certifications may result in compliance issues and hinder your business’s ability to participate in certain industries or markets.

- Increased Costs: Choosing an unreliable supplier may lead to inconsistent supply, causing operational disruptions, production delays, and increased expenses in rush orders and emergency solutions.

- Reputation Damage: ESD-related issues can tarnish your company’s reputation. A single incident of damage can lead to customer dissatisfaction, loss of trust, and a negative impact on your brand’s image.

- Lost Opportunities: Inability to meet customer protection requirements can result in lost business opportunities and contracts. Many customers in industries such as aerospace, medical devices, and electronics demand robust protection measures.

Final Thoughts

The importance of choosing the right foam supplier cannot be overstated. The quality of foam and the expertise of the supplier can significantly impact the effectiveness of your protection measures. By considering factors such as quality, certification, range of products, customization options, technical expertise, consistent supply and delivery, cost-effective solutions, customer support, and environmental responsibility, you can make an informed choice that will safeguard your business against risks and ensure the longevity of your products and reputation. Remember, the cost of choosing the wrong foam supplier can far exceed the price of the foam itself.