A human is a creature in need. These needs need to be met and these needs are being met. How are they satisfied? They are satisfied by manufacturers and service providers who are constantly looking for what consumers need and are constantly researching new and new wants and needs. Satisfying desires and needs can be for individuals as consumers, but it can also be for companies as consumers who would take a semi-finished product and then use it again in the production process in which they would refine it.

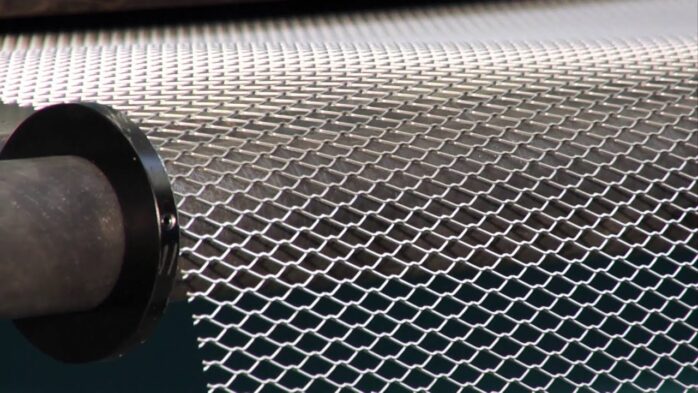

The products that consumers would buy can be of any nature. It can be food, it can be nutritional raw materials, it can be products that will satisfy an existential need, and even products from the metallurgy industry that would be used to make a product. Metallurgy products can be bought by individuals in order to use them in building a house, making a fence, or for some other purpose, but they can also buy companies for which these products have the meaning of a semi-finished product which would then be used in the production process.

The industry that deals with metallurgy is an industry that always listens and follows the wishes of consumers. Although this does not seem like it at first glance, it still is because in this industry a number of processes are done that are at the request of the customers and have simply become a routine for the workers themselves and for the factory itself. There are different types of metallurgical and semi-finished products that are purchased by customers (whether they are individuals or not). These constructions and semi-constructions are subject to a process of metallurgical production and shaping, which means going through some processes. We are sure that until now you have not met with the processes that are most often passed and which are applied in metallurgical production, so today we will focus a little on metallurgy as an industry, but also on the processes that are applied. So let’s see together and find out more on this topic.

What does this production process mean?

We are sure that many of the readers, but also people in general, are not familiar with what the production process covers from the aspect of metallurgy, but that is why we are here to clarify and explain this process. Metallurgy as a process does not only mean casting and making shapes of metal, but it also means fabrication, ie processing of metals and giving a new shape which will then be used as a product by people in further processes. This means that we have ready-made larger pieces of metal, smaller pieces of metal, wires, and many other accessories that are used through various work processes to get the final product.

What processes are known in metallurgy, ie in metal processing?

As in any production, in this type of production there are certain processes that need to be passed to reach the final result – finished or semi-finished product that can be used in further production. There are several of these processes, and today we will try to explain some of them. So let’s see something more about the production processes from the aspect of metal processing.

- Cutting and slicing of metal – this is one of the most common processes used in processing and production from the perspective of the metal processing industry. This is because metals are usually made in larger shapes so smaller pieces must be taken from them or smaller pieces need to be cut to be added to a larger piece and so on.

- Folding and making various shapes – in addition to cutting pieces or making some cuts in the metal itself, you can also fold it where it needs to be folded or fold it to give it a shape and figure. This is used primarily in processes where you need to get a shape made of metal or you need to get a construction that should be according to certain dimensions and size.

- Making prints in the metal itself – in addition to being able to shape or make cuts out of it or in it, prints can also be made on the metal itself if needed. For example, this process is used when a stamp needs to be made on the metal product itself or it needs to be deepened, so with the help of force and pressure from the machines, an impression is made that will make a certain depth in the metal.

- Extrusion or flattening of the metal – if a figure is uneven and you need a flat or straight figure, then this process should be used. This process is an integral part of the processing because most often the wishes of the clients is to get something that will be right and can be used as such in the process of further use or finishing.

- Writing or drawing on it – in other words engraving is part of the processes used in processing. It is a process in which with special lasers or special strings that work under pressure from the machine certain texts are written or certain drawings are drawn, logos of the metal itself and thus the client’s request is fulfilled.

These are just some of the goal setting shareware that you can use. For a detailed explanation of these, but also of the other processes that we did not list, the experts have already made a detailed review and their explanation, and to learn more and get to know each other better, visit https://levstal.com/blog/ what-is-metal-fabrication/.

What are the categories of processing of such materials?

There are several categories of metal processing as a material. It is clear that not every production can be general and the same, so there must be categories. Let’s see in this type of processing and production what are the categories:

- Structurally – the first category of processing is a category that includes making ready-made shapes, ready-made bases or components that will then be used for finishing and work processes such as construction, construction of something and the like.

- Commercial – this type means making a lot of packaging from this material, making the exterior of cars, making billboards which are also a kind of commercial product, etc.

- Industrial – this includes the manufacture of equipment or tools and other auxiliary accessories, but also includes the production of products that will then be refined.

If you have not had any information about this type of processing before, now you have a ton of information that can make things much clearer and more explained to you than they were before.