To begin with, Rotary motion refers to the process in which you turn round and round in circles. For example, the wheels of a vehicle are always in rotary motion when the vehicle is moving. While in the other case, linear motion is the process of moving in a particularly straight line. Like making use of a paper trimmer. While reciprocating motion is moving front and back in a straight line. Like cutting something with a saw. While Oscillating motion refers to the swinging from side to side motion like a clock pendulum. To learn more about rotary systems, visit IntelLiDrives.

Rotary systems could have come from using logs for rollers. But before then they were wooden disks which consisted of three different planks that were joined together using transfer struts.

Then with time developments took place and iron hubs changed to greased axles and then a tire came in with an iron ring which turned to the rim of the tire to enhance its rotary movements.

From this article, you’ll know what Rotary systems are all about. And how they have been used to get tasks done by making use of rotational motion. You’ll also know how machines could be joined together to know to make very important compound machines.

Rotary Systems in Simple Machines

There are about only six simple machines available in the science world. These include an inclined plane, a wheel and axle, a lever, a wedge, a pulley, and a screw. Simple Rotary Systems are not stressful and quite basic. They are very simple tools that can help you accomplish different jobs and tasks that are related to equipment moving in a rotary motion. Think of your simple blender for example. It is an easy rotary machine that aids one to grind things put inside without the use of force faster and with ease. These rotary systems can be implemented into other machines to create compound machines like this blender, and big machines used for production. Potential applications are seen in process automation for closed-loop control, mobile control panels with integrated safety functionality, mobile robots and motion control. The roll-out of 5G wireless technology is expected to make an outsized impact on automation and control applications, with its strong focus on machine-type communications and support for the Industrial Internet of Things (IIoT). 8.3.2.1 Less Time Consumption and Reliable Products are the Outcomes of the Automation in Machine Manufacturing.

Potential applications are seen in process automation for closed-loop control, mobile control panels with integrated safety functionality, mobile robots and motion control. The roll-out of 5G wireless technology is expected to make an outsized impact on automation and control applications, with its strong focus on machine-type communications and support for the Industrial Internet of Things (IIoT). Less Time Consumption and Reliable Products are the Outcomes of the Automation in Machine Manufacturing.

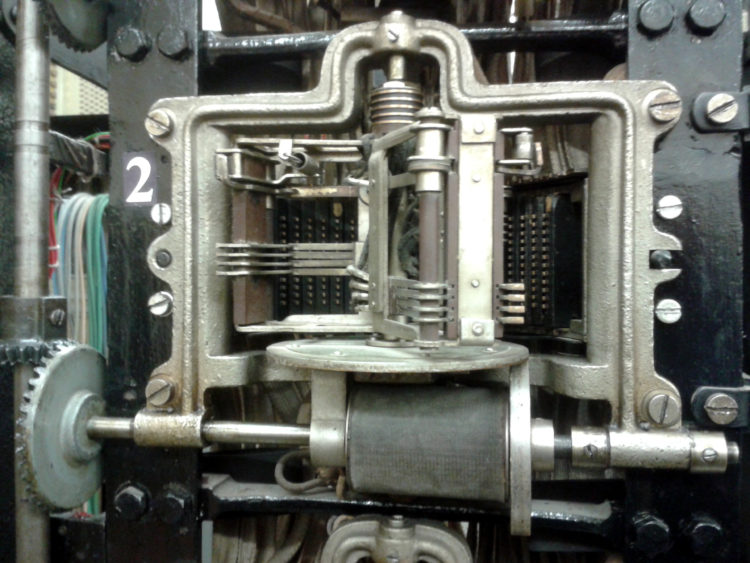

The term factory automation describes the methodologies or systems that employ extensive electronic and mech automation in order to control tasks and processes that have limited human input. Industry 4.0, also called smart manufacturing, describes the fourth industrial revolution, or the use of data with automation in manufacturing technologies. As discussed above, integrated factory automation is the complete automation of factory-related business and production processes through computerization.

Rotational Motion Transmission

Rotary systems use rotary motions to help people have more tasks done while all you have to do is find ways to physically move the machine. Either by using electronics to control it is doing it manually. Some other rotary systems can help you with the movement that you don’t need to do anything but put in a little force to make it work.

Think about how bicycles work. This is a compound rotary machine that helps one move from one place to another. All one has to do is sit on the bike and simply pedal away. It is way easier to do that than to walk all the way. Same thing with cars, motorcycles, lorries and other vehicles like these.

Even machines or robots that are used to produce goods and products in manufacturing companies, especially those that are used in the mixing of the raw materials have a lot of rotary motion being done by rotary systems in the equipment being used.

They all work and make the entire machine rotate in a particular circular motion. In the case of these machines that are used for production in Manufacturing companies, the rotational motion of the wheels is taken and used into the amount of the distance traveled or in this case, used in the efficient mixing of the raw materials which would give perfect raw materials that would be the end product and be sold to the customers of the industry.

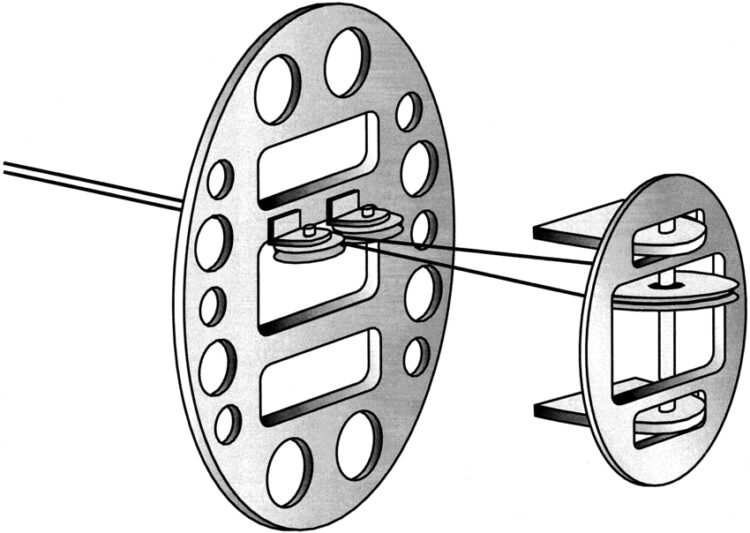

The simple machines that can take rotary motion into a different type of motion do so by taking the rotary motion to linear motion while being in contact with the materials they want to continue going in circles.

To understand think about how a large massive blender works. Like the types used in production firms. It takes in all the ingredients of raw materials and blends them making use of both rotary and linear motions together. Thereby mixing them all up to get the particular product necessary from the mixing process.

How does Rotary Systems work?

The blender is not a simple machine but a compound one. This is because it joins the axle and wheel together with gears. When the blender is turned on, it takes the rotary motion on the blending wheels and then the wheel and axle after changes the rotary motion to linear motion while going through the raw materials thus creating friction for it all to work properly.

There is a great need for the implementation of rotary systems in manufacturing and producing firms.