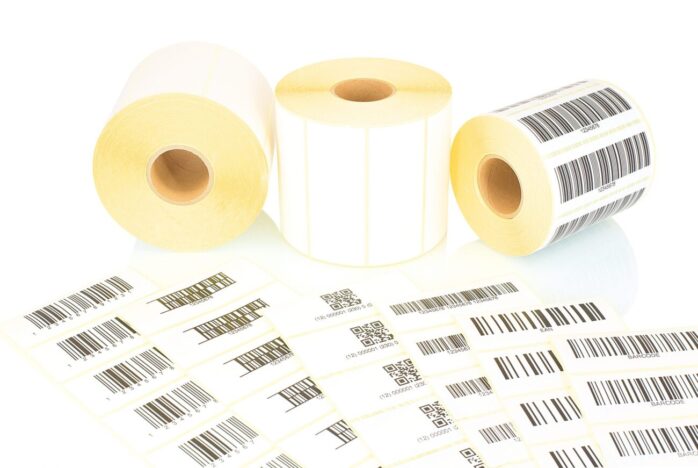

In order to recognize some products, you need to stick special stickers on them. These labels will contain product information: price and barcode. We encounter labels most often in stores because every product must be labeled. Each customer will know the price of the goods, and when he comes to the checkout, the seller will scan the barcode and the goods will be sold. There is a wide variety of thermal stickers and each of them has its own characteristics. Thermal stickers are most often used on goods with uneven surfaces such as fruit, vegetables, and the like. They are suitable for labeling products whose journey from the producer to the final consumer takes a long time.

They are suitable for labeling products that are stored in a dry place and do not come into contact with moisture. Most often, it is a matter of labeling or declaring consumer goods, outer packaging, or pallets, but they can also be used to label products that are frozen. They can contain a range of product data – from barcodes, logos, graphics and text content, and product expiration dates to serial numbers. Such information on labels is necessary for product identification and tracking. They are sensitive to light, so their service life is slightly shorter than thermal transfer labels.

Considering the resistance to different temperatures as well as what is their primary purpose, there are several things to pay attention to when choosing.

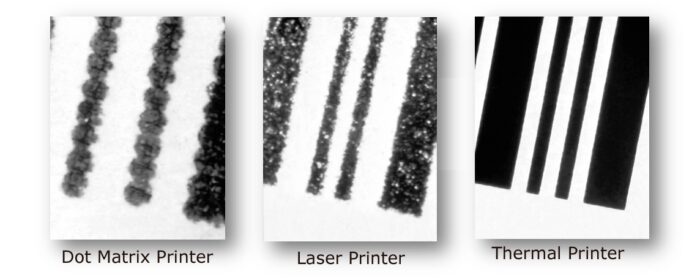

Print quality

In order for the print to be of satisfactory quality, it is best to choose paper stickers because they have strong adhesion to the ink, they also easily absorb the color and the mark is long-lasting.

High temperatures and waterproofing

These factors are crucial when it comes to making stickers such as vignettes.

Color

When we talk about color thermal labels, we will not make a mistake if we say they can be any color the customer wants but the most common is white or some pastel color so the text on it is visible, which is also its primal function.

What is the most common application of thermal labels?

The most common application of thermal labels is in supermarkets and weighing scales. They are typically used in two qualities, namely thermal eco and thermal top. Thermal eco is of lower quality, less wear-resistant, and the surface is matte. The thermal top is more resistant to scratching, and the surface is more shiny. Many customers use these labels for semi-finished products, one-time use, or semi-printed labels where the logo is printed on the label, and so on.

What about thermal stickers for clothes?

Stickers for clothes are a very powerful way to decorate a simple item of clothing that you want to give your personal stamp on. Unlike thermal labels, these stickers are not self-adhesive but have an adhesive on them that is “activated” at high temperatures, that is, when you run an iron over the sticker. In this way, the sticker will be copied onto the fabric.

Lifetime

It is difficult to say what the shelf life of thermal labels and stickers is because it depends on many factors, and weather conditions are perhaps the most important, as well as the quality of production. What we can say with certainty is that fabric stickers are more durable and survive at temperatures up to 60oC.

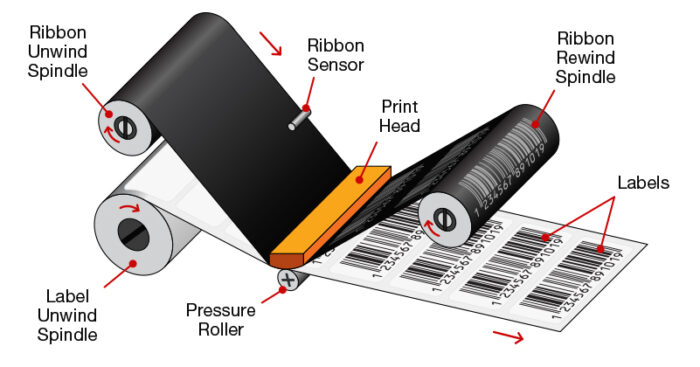

Working principle of a thermal printer

Labels intended for thermal transfer are printed using a thermal transfer printer. Thermal printing uses heat to print the substrate and is often a better choice than ink or laser printing. It is excellent in situations where the speed or durability of printed material is important; in practice, the so-called thermal printing.

Thermal transfer labels in a roll are available in multiple dimensions, quantities, colors, and materials in order to be applicable in a wide range of needs of different industries. They can be made of paper, plastic, metal and resistant to chemicals as well as high and low temperatures. Security thermal transfer labels are intended to prevent product packaging from being opened, counterfeiting, or product theft.

Thermal transfer printing is also used to print plastics, textiles, or ceramics. More expensive devices, the so-called thermo-sublimation printers transfer color contactless (by spraying), which reduces the wear of the print head. In most cases, thermal transfer printers are also capable of direct thermal printing.

Unlike paper direct thermal labels, thermal transfer labels are more suitable for labeling products whose journey from the producer to the final consumer takes a longer period.

They are suitable for labeling products that are stored in a dry place and do not come into contact with moisture. Most often, it is a matter of labeling or declaring consumer goods, outer packaging, or pallets, but they can also be used to label products that are frozen.

Final thoughts

When used appropriately and designed well, stickers can be a great marketing tool for almost any business. The problem is that most people have no idea where to start when it comes to designing stickers. When used appropriately and designed well, stickers can be a great marketing tool for almost any business. You need to think about the message you want to convey, the actual copy of the label, the size and shape, the typography, and of course the actual printing process.

Another important thing to keep in mind is that in order to achieve the desired outcome when printing labels, you should make sure that you choose a reputable printer that has a lot of experience in label printing. However, this is about improving the business and the way to promote the product, so it is necessary to invest a little more money in order to get the advertising you deserve. Consider this a smart business investment that will undoubtedly pay off.