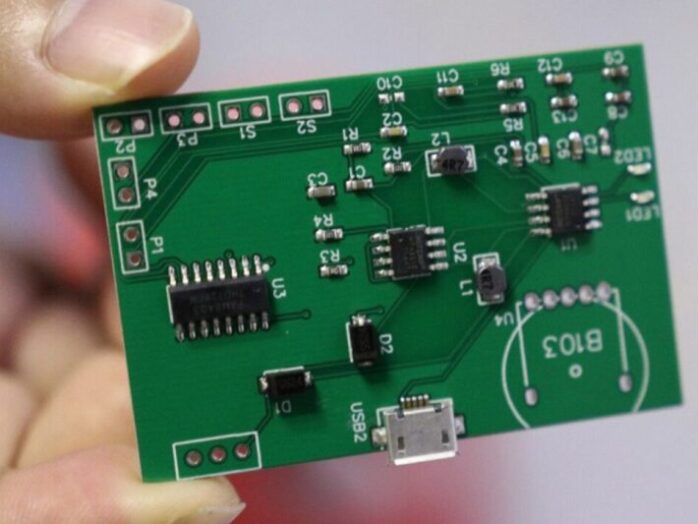

In a manufacturing plant that produces printed circuit boards, every single material matters. The two, most popular options are standard and aluminum PCBs, which are most commonly used for powering different consumer and commercial electronics. However, each of the options has its own properties, which is why you have to carefully consider what suits your needs best.

This is why you might be wondering – should I choose aluminum or standard PCBs and which one is better? Simply said, it’ll depend on the project you’re working on and in order to make a decision, you must learn how each of the options is different. Let’s take a closer look at the comparison guide below:

1. The Costs Will Vary

When you need a PCB, the cost is, perhaps, the most crucial factor to consider. Though the value of metals is constantly changing, you should know that standard PCBs – that feature copper cores – are usually more costly, mostly because the substance is rarer than aluminum. Hence, when you’re establishing a budget and when you’re working on your design, you could opt for aluminum, instead of standard boards if you want to save some cash.

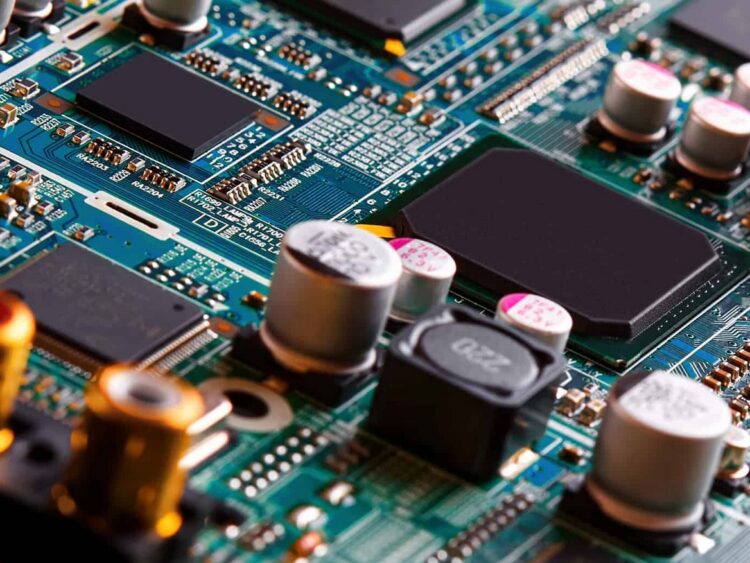

2. The Heat Conductivity is Different

If you have to be extra careful about managing the temperature in your design, you should remember that aluminum will always stand out over cooper, due to a little thing named heat conductivity. Thermal or heat conductivity relates to the level of heat transported within the metal, and when contrasted to copper, aluminum offers a quicker transfer speed.

Standard is more suitable if there will be extremely high temperatures that could damage some of the parts, or if you’ll have to use high power. Hence, another thing that you’ll have to consider is the application and heat requirement, meaning that you need to choose the material based on what you’ll use the PCB for.

3. The Electric Conductivity is Important Too

As you already know, both of these materials will conduct electricity, but the level of conductivity will vary for both materials. When talking about electric conductivity, copper is naturally more competent at it, and if your design requires electric conductivity, you must ensure that you opt for copper. Basically, whenever you have a plan that requires this important feature, choosing standard PCBs is always better.

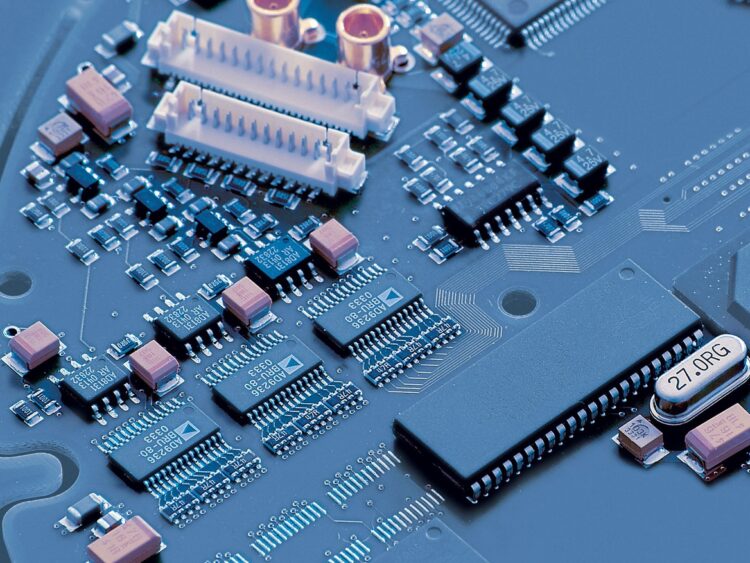

4. The Amount of Layers Needed

Printed circuit board design most commonly has 2 models – single and multiple. This means that they could have either one or several layers. When talking about these two options, aluminum is a fitting alternative for single-layer boards, mostly because it’s difficult to manufacture aluminum boards with several layers. If you need several layers, standard PCBs are better due to the fact that it’s easier to manufacture a board with several layers from copper.

5. They’ll Impact Our Environment In Diverse Ways

According to the experts from pcbonline.com, this is one of the latest things that you’ll have to think about, especially if you’re trying to make your company ‘greener’. If you’re Eco-conscious, aluminum is a better option for a wide range of factors. For starters, aluminum could be found in nature and it can also be easily refined, manufactured, recycled, and it’s non-toxic.

However, with standard PCBs that most commonly feature cooper, these characteristics are basically non-existent, which means that they cannot be found easily, you’ll not be able to refine them in an easy way, and more importantly, it’s more toxic for our environment. Hence, consider whether or not you want to be more Eco-friendly when choosing the material for your PCBs.

6. Electrical Resistance is Crucial!

The expression ‘resistance’ relates to the quantity of friction the material has to the course of electrical power. When it comes to the layout of the printed circuit boards, it’s an important aspect to think about, especially since it’ll affect the other components, as well as the function of the item. Copper is denser than aluminum, hence, it’ll provide you with less resistance. Hence, if you need more delicate circuits and quicker power transfer, standard PCBs might be the most fitting option for you.

7. The Durability of The Elements

Durability or as it’s also referred to as ductility is the process of undergoing stress before a specific item breaks. Although both materials are metal, they’re flexible, however, there are some differences between the two options. Generally, standard PCBs offer more ductility, which means that they’re more suitable for PCBs that must be more durable. If not, you could choose aluminum.

8. The Weight is an Essential Factor

Since there is a greater density per item area, copper is frequently heavier than aluminum. And, like everything else from this list, this is an essential factor to consider, especially since it’ll influence the overall design. If you need it for an application that features a light-weight design, aluminum is definitely a better choice. However, if you don’t need to worry about the overall weight of the printed circuit boards, copper is accepted with open arms.

9. Drilling Can Be Easier or Tougher

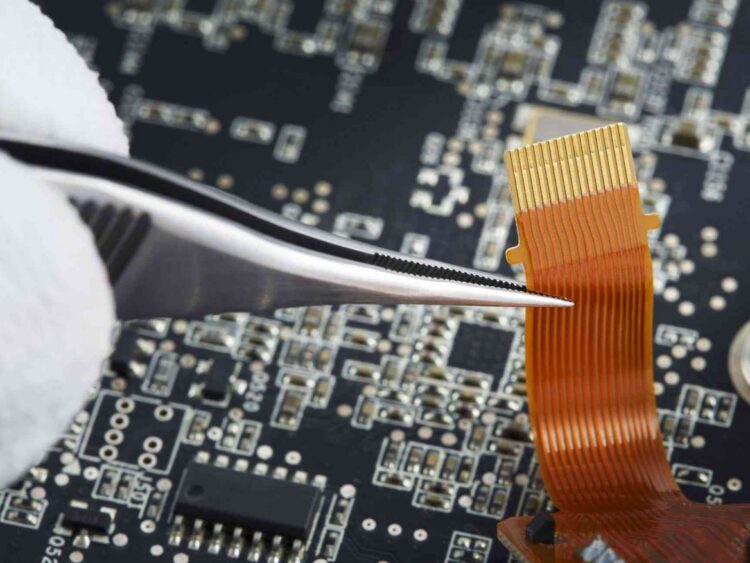

You probably know that your PCBs will have to be drilled. The general design of PCBs is built with a basic layer of material such as fiberglass, and the metal layer is placed on top of it. With a multi-layer board, this is something that is done several times.

When thinking about drilling holes in the boards, copper might be more suitable, but, the same cannot be assumed about the other options – and this is exactly why aluminum boards are most commonly made with one layer. Hence, if there are holes that need to be made, you might want to choose a standard PCB.

Conclusion

If you need to order a large number of printed circuit boards, there will be a lot of considerations when it comes to the material you should choose. Keep in mind, you must also consider the application and your entire project, especially since this can help you make the entire process of choosing the material easier.

So, now that you know all the differences between the two options, you might not want to lose any more of your precious time. Instead, you should return to the beginning of the list above, go through it once again, and then determine which material might be more suitable for you.