An impact driver and an impact wrench are both powerful tools used in various construction applications. Both tools use a hammering force to generate rotational torque, making them highly efficient at completing a variety of tasks within a short amount of time. Despite their similarities, there are also some distinct differences between these two tools. To make the right tool choice when tackling a project, it’s important to understand these differences.

Definition of an Impact Driver

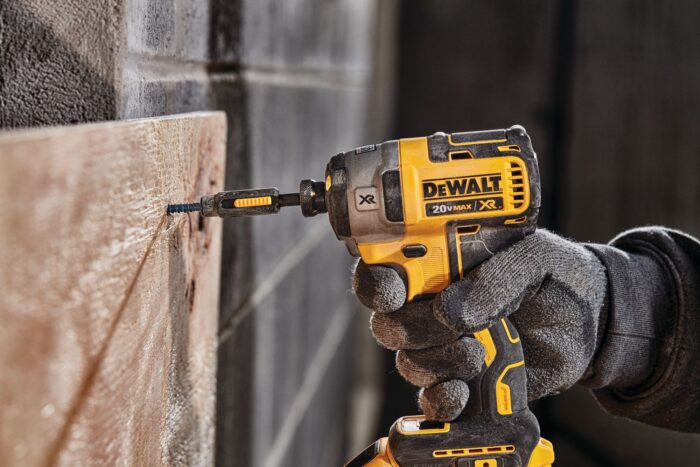

An impact driver is a powerful tool used to drive screws and other fasteners with greater force than is achievable by hand. It uses a hammering action to “sink” the fastener into the material. By using an interchangeable bit, it can drive any type of head you need, from Phillips and square to hex, Robertson, and Torx. Impact drivers are designed for high-end professional use and are available in cordless or corded models.

They are lighter in weight than impact wrenches, allowing users to work in tighter spaces when needed; they also have less vibration than an impact wrench during operation. The tools’ ergonomic designs often make them easier to handle and maneuver compared to standard drills or screwdrivers. They typically have variable speed motors that range from 0-2,400 RPMs so users can adjust the force output according to the application at hand.

Definition of an Impact Wrench

An impact wrench is a very handy tool used for driving and removing nuts and bolts quickly and efficiently. It works by using a combination of both electric force and brute power to produce higher torque than would normally be achievable with manual tools. The electric force is generated from an internal spring-loaded hammer that strikes the bit repeatedly when the trigger is depressed, providing greater speed and power.

These tools are typically used in a garage or automotive applications for loosening lug nuts or bolts on tires, breaking rusted or frozen bolts free, and working with drive shafts, suspension systems, and other parts on cars, trucks, and heavy equipment. Impact wrenches can come in various sizes and they can also be pneumatic or cordless battery-powered.

Differences

They both have a similar working principle, but they have some distinct differences as well. Let’s explore the differences.

Size

The main difference between the tools has to do with size and power. Drivers are smaller, lighter tools, often measuring less than 6 inches long. They tend to weigh around 2-3 pounds and are very portable. Because of their size and weight, they can be more difficult to control but can reach tight spaces that are difficult to maneuver with a larger tool. An impact driver is best suited for smaller tasks such as driving small screws in drywall or delicate fastener types, like sheet metal screws.

Impact wrenches pack much more power than drivers into a larger body size. Usually measuring over 10 inches long, this tool has a more solid frame that allows it generates higher torque (power), making it better suited for tougher applications such as removing large bolts or lug nuts. Wrenches can also produce fastener spin-outs at significantly higher rates than drivers allowing you to complete tasks faster than ever before!

Torque

Torque is the tightness of a fastened screw or bolt, measured in inch pounds. Drivers and wrenches provide more torque than their drill counterparts, enabling the user to tighten or loosen larger fasteners. The torque delivered by a driver or wrench can range anywhere from 40 inch-pounds up to 600 inch-pounds depending on the size and type of model.

Impact drivers provide a much higher torque than traditional drills but still remain relatively low compared to impact wrenches in most cases. An impact driver typically tops out at around 2,000-inch pounds of torque meaning it can provide significantly more tightening power than an ordinary drill or screwdriver.

Impact wrenches, on the other hand, are designed for much higher output and can typically deliver up to 6 times as much torque as an impact driver due to their geared design. While these heavy-duty devices are typically used for removing nuts & bolts from automobile engines, they can be utilized for tasks requiring greater amounts of force such as setting railroad spikes & anchors into concrete walls.

Price

The price of these tools varies significantly from manufacturer to manufacturer and from model to model. Generally, an impact driver is cheaper than an impact wrench; however, the features, design, power, and battery life are considered when comparing prices. A cordless driver usually costs less than a cordless wrench but can still provide powerful performance for small tasks around the home. On the other hand, a cordless impact wrench is more expensive because it has improved power and torque rating. It is better suited for larger projects or DIY jobs you might undertake.

Tips for using these tools

Using them requires a bit of know-how, as there are several key differences between the two tools. Knowing how to properly use your chosen tool can help prevent damage and make your project run smoother.

Always ensure that the tool bit is securely seated in the receiving socket before applying pressure to complete your task. Doing so will help prevent any accidental slippage and ensure you get maximum efficiency from your tool. Make sure also to check if there are any hard materials in a range that may be affected by sudden impacts created by these tools — metals can easily become damaged if too much force is applied so take extra care when using either near metal objects.

It’s important to remember that while powerful, these tools don’t always yield great results on softer materials like wood or plastic — it may be better to consider other lighter tools such as drills instead for those types of jobs. When used correctly and responsibly with regard to application and material type, an impact driver or an impact wrench presents users with a lot of versatility while completing DIY tasks around the home!

Conclusion

For most do-it-yourself projects, a driver will provide sufficient power to complete the job without having to invest in a wrench. A wrench is more appropriate for those tasks that require more torque for faster results. Whether you choose a driver or a wrench will depend on your individual needs and preferences — but no matter what kind of job you’re tackling you can’t go wrong with either tool!