“I want to print t-shirts!”

You have probably heard this from someone eager to start their t-shirt printing business. Perhaps, you have even said this out loud to yourself!

The excitement of envisioning a design idea can quickly die down once you are forced to face the more technical side of custom printing. The first question that probably comes to mind is: which apparel printing technology should I pick?”

Choosing the right one for your printing business is the first and most crucial building block that leads to happy and loyal customers, immense cost savings, and a scalable business model. Plus, you also have to answer the following questions:

- How cost-effective is it?

- Will my design work with it?

- Is the printing technology eco-friendly?

- Will it sustain the business during the pandemic?

Of course, the market is filled with options for apparel decorators. According to an SGIA report, screen printing and Direct-To-Garment printing are most common amongst them at 84.2% and 36.8%, respectively. However, 31.6% of apparel decorators plan to purchase DTG—a figure that is the highest, the study reported, and for a good reason.

This article discusses the two printing technologies in detail and compares them on multiple factors, and also answer why printers prefer using DTG:

Direct-To-Garment [DTG] printing

This is a printing technique that sprays the ink onto the fabric, which soaks into the fabric fibers. DTG printing resembles a lot like printing on paper. But it is done on clothing. Since it is a relatively simple spraying-and-drying process, it is easy to print one-offs with DTG printing.

For instance, once your end-client orders a personalized t-shirt on your web2print software solution, you will receive the order, print your design on the t-shirt using the t shirt design software, and send it directly to them. Simple. DTG printing requires no prior investments, and each product is printed on-demand. No more bulk ordering!

Types of designs apt for DTG printing

There is no limit to what you can print or the colors in which you can print. You can even allow your end-clients to choose from more detailed designs and photorealistic imagery. This is an essential element for businesses that want to experiment with techniques and colors using their product design tools. That is why printers prefer DTG!

But you have to ensure the elements being printed are 1005 opaque. Otherwise, they would not translate well onto the fabric. It is best to use solid colors for optimal results. Apart from that, there are no significant drawbacks of DTG printing.

Eco-friendliness

There is no doubt that DTG printing is more sustainable. It not only allows end-clients to print one-offs but also prevents overproduction and textile waste. Now that is a business model, which is a game-changer for printing businesses.

Since many end-clients are looking for smaller print jobs, this makes DTG printing cost-effective and eco-friendly. Plus, this also leads to a shorter printing cycle.

Is DTG printing right for your printing business?

Absolutely! There is no doubt about it. DTG printing offers a hassle-free way to get the products ready for your end-clients. Combine it with the power of web-to-print software, and you have yourself a robust and dynamic eCommerce business that sells high-quality print products and excels at workflow print management. You also do not have to worry about keeping products in bulk.

There is no extra setup time to start printing, and so your orders can be fulfilled as soon as the end-client places an order on your web-to-print software solution. There is more freedom to run your printing business; however, you like, without burning a hole in your pocket.

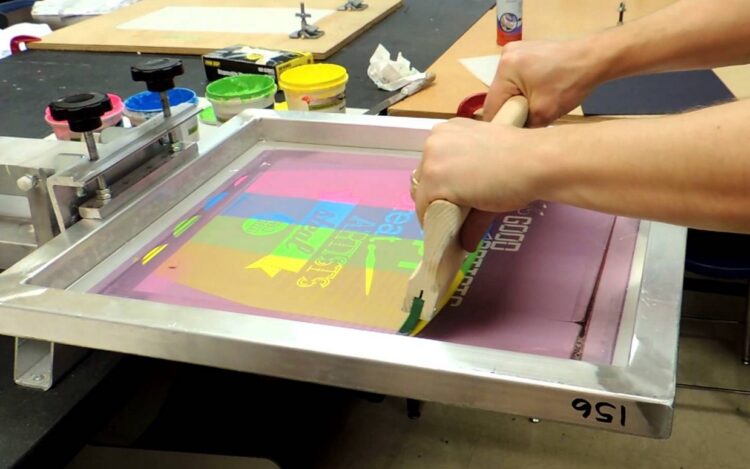

Screen printing

This technique involves pushing the ink through a woven screen, also called mesh stencil, onto the fabric. The ink does not soak into the clothing material but lays on top of it. The more layers a design has, the longer it will take to print it. The design also feels thicker on the product.

Since it has a longer setup time, screen printing is mainly used for printing items in bulk. That makes it an expensive method, and printing custom products such as a t-shirt or a mug leads to costly overheads and longer printing cycles.

Types of designs apt for screen printing

If you want to make screen printing work efficiently with you, choose solid graphics without small details, e.g., geometric designs, shapes, typography, and symbols.

Creating stencils for advanced designs is complicated, and getting them right during the printing process is not guaranteed in this technique, even if you use html5 product designer.

In addition, since each color is applied separately. Therefore, it is not wise to have too many colors in the custom design of the printed product. Printers usually limit the number of colors (which is generally nine) that one can have in the designs using the html5 product designer.

Eco-friendliness

As a web-to-print store owner, you must also know how the printing business impacts the environment. It is not wise to ignore the sustainability factor of screen printing. Printers who deploy this technique order in bulk and then send out the orders as they come in.

This workflow often leads to overproduction, which not only burns a hole in the pocket but negatively affects mother nature. If your screen printed-products do not get sold, they might end up in landfills, contributing to pollution.

Is screen printing right for your printing business?

If you sell print-ready products that do not involve too many colors or have intricate designs, then yes, screen printing is right for you. Plus, you should be able to take orders between 5 to 100. All of this adds to the final price of your screen printing bulk order.

No matter how careful you are, screen printing does take a toll on your financial strength, and given how every printer is trying to save costs due to the pandemic, it is best to go with DTG printing. It is lighter on the pocket for sure and yields optimal results.

In conclusion: use DTG instead of screen printing

Although screen printing processes can print t-shirts quickly, their setup time is too long, which is only ideal if you want to print one design at a high volume quickly. If you will print multiple designs—which is what the case should be—go for DTG printing.

Screen printing is also profitable for small order volumes, while DTG printing offers a much more cost-effective alternative. For printers who want to build a business model accommodating smaller orders, DTG printing would be highly profitable for them!

Therefore, save your time and cost by getting print-ready outputs hassle-free. If you are looking to deploy a web-to-print software solution, please do not hesitate to contact companies such as Design’N’Buy Web to print.