Surface treatment combines different processes and technologies that modify the surface properties of manufactured components and models. We enable the improvement of the surface functions of the prototype, as well as the components in small series. For example, glossy paints, logos, and more can be applied to your components.

Where is it used?

It is used after the company’s production processes and services. Surface treatments are used to obtain the desired designs and perfect surfaces with appropriate properties – optical and functional. That is why surface treatment is especially important as the end of various production processes.

With a variety of services, you can meet your individual requirements for component surfaces. Coating in particular to ensure that each component achieves the best possible qualities. Of course, the whole production process is adapted to the needs.

Which processing processes and technologies are a complete hit in 2024?

1. Color

Painting of components according to color specifications and color samples. In order to achieve the highest quality painting, painting is often preceded by other surface techniques, such as sanding. After intensive cleaning, the component is finally painted individually. Painting allows to improve the decorative properties of the produced models. Once the prototype is completely dry, further surface coatings, such as printing or laser marking, may follow.

2. Rays

Blasting is a mechanical process that cleans the surfaces or prepares them for further processing. In blasting system, different blasting material enables the appropriate processing of grains according to the desired requirements.

3. Colorize

Dyeing as a specially developed process has the property that dyeing takes place without the application of material. In addition, the properties of the components do not change. Dyeing is especially used for components produced by the SLS process. In this surface treatment, the component is completely dipped in the desired color. In this way, each joint and column is carefully recorded without coating. Staining can be combined with chemical smoothing, sanding and infiltration.

4. Steaming

Vapor deposition as a performance of our surface coating produces components that, after vapor deposition, have a completely identical appearance of chromium. The decisive factor is, above all, the correct finishing and precise preparation. In order to achieve a particularly smooth coating with a high degree of reflection, a primer is applied in the inner paint compartment as needed. Steaming is used, for example, in reflectors (mirrors).

5. Printing

You can enhance the models and prototypes with letters or logos if desired. This includes an appropriate printing process for the various requirements for the smallest images on prototypes, as well as logos for components in small batches using screens, pads, and digital printing.

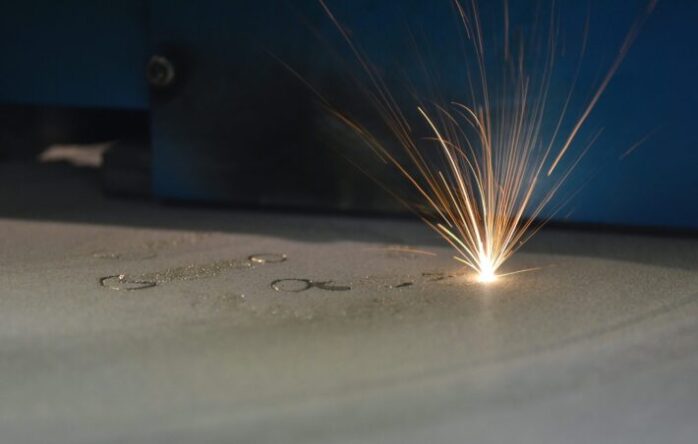

6. Laser marking

Optionally, models and prototypes can be displayed with the letters, engravings, or logos you need using laser technology. There is a wide range of laser marking applications, as a wide range of engravings can be applied to a wide range of contours. In addition, laser inscriptions are particularly resistant to environmental influences.

7. Surface grinding / tumbling

It is especially used for metal components. In the case of vibratory grinding, the grinding wheels are located in a rotating bowl. The movement of the grinding wheels smoothes and degreases the surfaces as needed. Learn more about the vibratory machines.

8. Chemical smoothing

Chemical smoothing is used as the technology of our finishing of plastic components produced by the SLS process. The surfaces of the prototype are smoothed in different thicknesses, depending on the requirements. In this process, the SLS components on the top layer liquefy and rearrange the powder particles. This change creates surfaces that are smooth and have a Shiny Smooth layer. After this process, prototypes also have the advantage of being more resistant to dirt.

9. Heat treatment

Heat treatment is especially aimed at improving the functions of the components. The properties of metal finishing materials are improved by this method in terms of the degree of hardness, resistance or temperature resistance. Heat treatment involves various services, some of which are integrated into a particular process.

During hardening, the components are first heated to a specific temperature and quenched after a short period of time. Hardening, like tempering, is therefore one of the thermal heat treatments. Hardening as a metal finish improves the resistance of components in particular. The remuneration takes place after hardening by tempering the steel components. It is used when the components require high strength and low crack formation.

The nitriding is carried out by a supply of nitrogen, and also achieves hardening of the surface. It is used for steel components that require temperature resistance. The components can also be completely manufactured before the heat treatment since no further deformation takes place.

10. Infiltrate

During infiltration, the components are sealed with impermeable liquid, without applying materials or coatings. This affects the porosity and strength of the material. The components are immersed in a certain infiltration, such as epoxy resin or acrylic, so that sealing occurs even in hard-to-reach places.

11. Polishing/grinding

Polishing and sanding are used depending on the surface preparation requirements. On request, mechanically produced or additively produced components are polished using rapid prototyping to high gloss.

12. Powder coating

Powder coating as a technology achieves a resistant protective layer. The baking process combines the powder particles into a solid layer. Surfaces can have different structures and colors according to your wishes.

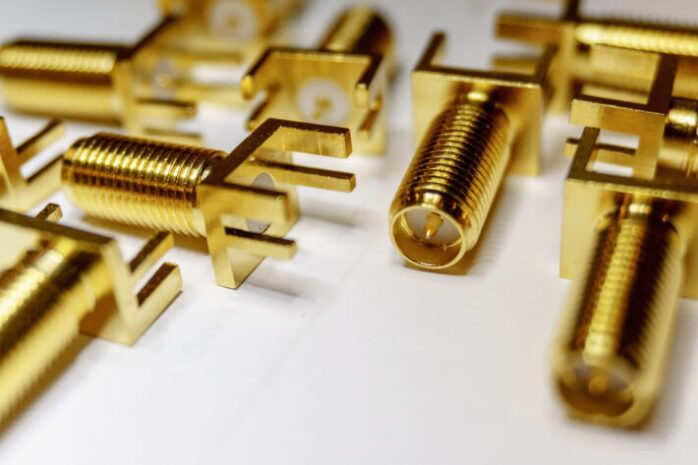

13. Anodizing

Anodizing refers to a process in which an oxide layer is produced electrochemically. Anodizing is used for components made of aluminum that should have a protective layer against mechanical and weathering. Anodizing produces pre-treatment structures (eg grinding, polishing, sandblasting).

Conclusion

A central feature of surface technology is the ability to produce additional models and prototypes. If, for example, you need components with improved properties, such as corrosion protection, our suggestion is to look for a solution through surface finishing.

Another important advantage is the ability to optically finish the components and thus improve the aesthetic and decorative properties. After the appropriate manufacturing process for your prototypes, the painting optically ensures the actual realization.