The success of any construction project hinges on various elements, a significant one being the choice of lumber. Quality lumber has a profound impact on the overall outcome of construction projects. The right type can elevate the quality and durability of your project while also improving aesthetics.

On the flip side, poor lumber selection could lead to structural issues, increased costs, and customer dissatisfaction down the line. Therefore, getting familiar with the various factors that influence the quality of lumber is paramount for contractors.

Understanding Types of Lumber

In the world of construction, choosing the right type of wood is crucial for the success of your project.

Softwood

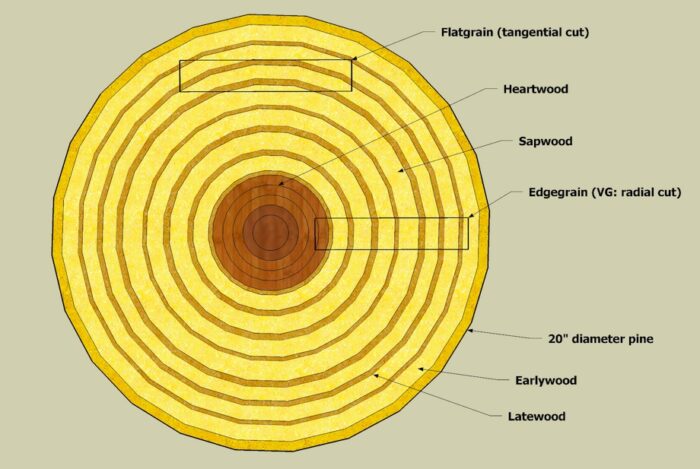

Softwoods, derived primarily from coniferous trees, are a popular choice in construction due to their versatility and affordability. Predominantly used in framing structures, their relative lightness and ease of manipulation make them a favored option. However, bear in mind that softwoods might not always be the perfect fit. Their suitability depends on the specifics of your project.

Hardwood

Contrary to softwoods, hardwoods come from deciduous trees. Noted for their high density and hardness, these types of lumber are ideal for projects that demand longevity and durability. From flooring to intricate furniture, hardwoods can handle it all. However, the increased quality comes with a steeper price, hence the necessity of evaluating the budget constraints of your project before settling for hardwoods.

Lumber’s Costs and Durability

The grading plays a pivotal role in determining the quality and characteristics of wood, influencing both its price and durability. High-grade lumber boasts fewer defects and a uniform appearance, making it an excellent choice for projects where aesthetics are paramount.

However, the superior quality of high-grade wood material often comes with a higher price tag.

Conversely, low-grade lumber is more cost-effective but is best suited for concealed areas of a project where visual appeal is less significant. By understanding the nuances of lumber grading, you can make informed decisions that strike a balance between quality, cost, and the specific requirements of your project.

Lumber Sizes and Uses

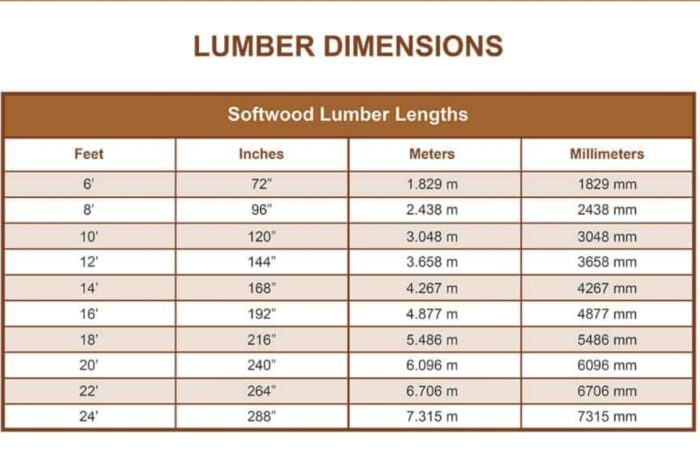

In the vast realm of construction lumber, a diverse range of sizes exists to accommodate various project requirements. When it comes to framing, 2x4s are the favored choice due to their optimal combination of strength and affordability. Conversely, 1x boards with their thinner profiles are better suited for interior applications such as cabinetry or trim work.

Ensuring the right size of wood material is matched to the specific demands of the project is essential for maintaining structural integrity and functional efficiency. By selecting the appropriate size, you can ensure that your construction endeavors are not only sturdy but also tailored to meet the precise needs of the task at hand.

The Moisture Content

The moisture content of lumber is a crucial factor that significantly influences its quality and appropriateness for diverse projects. Wood building materials with excessive moisture can undergo warping or shrinkage as it dries, leading to potential structural problems. Therefore, for indoor projects, it is essential to opt for kiln-dried lumber with lower moisture content, ensuring stability and minimizing the risk of future issues.

Conversely, outdoor projects require consideration of the wood’s exposure to the elements. In such cases, a slightly higher moisture content might be acceptable to account for the natural drying and expansion that can occur in outdoor environments. By carefully assessing the moisture content, you can select lumber that aligns with the specific requirements of your project and ensures long-lasting performance.

Spotting the Defects

While it’s true that no piece of lumber is flawless, certain defects can pose risks to the structural integrity of the wood. Knots, splits, and wane are among the common flaws that can diminish the usable area of the board or create weak points. Consequently, it is crucial for contractors to exercise vigilance during the wood material selection process.

Carefully assessing and choosing pieces with minimal defects, contractors can ensure the strength and durability of the project. Attention to detail and a discerning eye for quality are essential when it comes to selecting lumber that will contribute to the overall success and longevity of the construction endeavor.

Going Green: Certified Wood

Sustainability has become a key concern in construction. Choosing certified wood — lumber from responsibly managed forests — is a tangible way to contribute to environmental conservation. Aside from the environmental benefits, using certified wood can also enhance a project’s value, as more clients today are eco-conscious and appreciate sustainable building practices.

Leveraging Lumber Delivery

Efficiency and time management are paramount in the construction industry, as every moment counts towards project success. Lumber delivery services play a crucial role in optimizing logistics and saving valuable time. By utilizing these services, you can get lumber delivered directly to your construction site, eliminating the need for time-consuming trips to suppliers, visit BuildClub to know more!

This streamlined process allows you to redirect your attention and efforts towards other critical aspects of the project, such as coordination, planning, and execution. Remember, while selecting the right wood material is vital, ensuring efficient logistics through reliable delivery services is equally essential for maintaining a smooth-running and productive construction project.

Quantity and Purchase

Before you order lumber for delivery, a few factors need careful consideration. First, estimate how much lumber you’ll need for the project to avoid wastage or shortage. Next, take the time to compare prices from different suppliers to ensure you’re getting the best deal. Lastly, check that the wood material has proper labeling, including the type, grade, and size, to confirm it meets your project requirements.

The lumber selection process is not just about picking the first boards you see. It requires a comprehensive understanding of the various types of wood material, their grades, sizes, moisture content, and potential defects. Embracing sustainable choices, like certified wood, can also enhance your project’s appeal.

Lastly, don’t forget the convenience of lumber delivery service to keep your project running smoothly. Implementing these insights into your next project can significantly enhance the quality and efficiency of your work, ensuring client satisfaction and giving you an edge in the competitive world of contracting.