Milk is a food staple in households around the globe. We use it to pour on cereal. We drink it plain. It’s used in addition to other ingredients in baking. It’s used in nutritional products. We add chocolate syrup to it to make delicious, nutritious beverages. It has so many uses and is enjoyed in countries around the world. But the question is, if it’s in practically every household in the world, how does it get there?

Milk Production

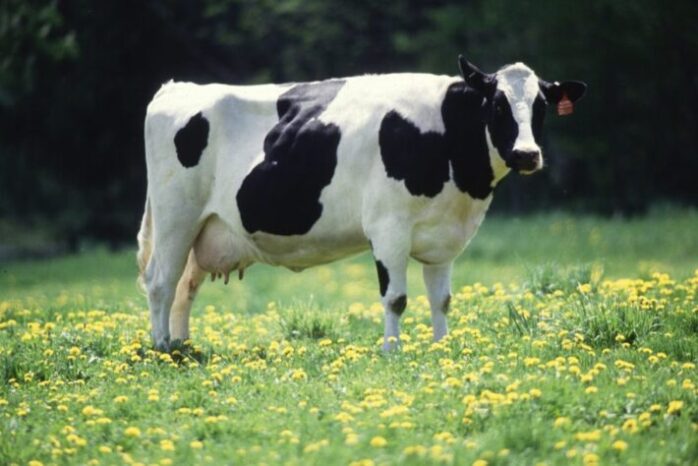

Before milk can be shipped, it must first be produced. Before milk can be produced, the cow must first be lactating. This can only happen after the cow has given birth to the calf. The milk then has to be extracted, and that’s done by using your hands or for bigger production needs milking machines are the preferred method. Milking machines have evolved. The first form of milk production was done by hand.

That eventually evolved into the use of the vacuum milking bucket. Which then evolved into the Surge hanging milker, a leather device that was fit under and over the cow’s lower back. The milker hung under the cow from a strap. This milking process would allow the cow to move around naturally rather than stand perfectly still during the process.

The Milking Pipeline

The milking pipeline was the next innovation in the milk production process. In this process, a permanent milk return pipe, along with a second vacuum pipe that encircled the barn and or parlor above the cows. This milking device shrank in size and weight as a result of eliminating the need for the milk container.

The sucking force of the nipples being milked by the vacuum system is what held the device up without the assistance of any other cumbersome devices. The milk would then flow into a storage tank by way of the milk return pipe and vacuum system. This process greatly reduced the need for physical labor to extract the milk.

Fully Automated Robotic Milking

In the EU in the 1980s and 1990s, the fully automated robotic milking system was birthed. The cow can choose her time of milking freely with this particular system. Thousands of these are now in routine operation around the world. The cow is fed nutritional concentrates every time it enters the milking unit. This is done to ensure the health of the cow.

This system also monitors the cow is not over milked which has caused health issues with cows in the past. Over milking a cow can actually negatively impact production because a sick cow doesn’t produce as much milk as a healthy cow. Cows are normally milked twice a day. Samples are taken from milk vats prior to collection and tested for bacteria, milk-fat, bulk milk cell count, and antibiotics before it enters the milk processing area. It is rejected if it doesn’t meet quality standards. A sample is also collected from each farm pickup prior to being pumped onto the tanker.

Pasteurization

Pasteurization is the process of heating the milk to a certain level for a certain period of time to ensure all harmful bacteria are killed off and then allowing it to cool down again without recontamination. This ensures the delivery of a safe and nutritious product for human consumption.

Homogenization

Homogenization is a process that involves pushing the milk through an atomizer to separate the fat into tiny particles to be evenly dispersed throughout the milk product. This process essentially prevents clumps of fat from forming and floating to the top of the bottle.

Separation

Separation is the process of rapidly spinning the milk through a centrifuge to separate the cream from the milk. The milk and the remaining cream are then remixed to create different milk products with different fat content levels. To produce different kinds of milk products such as 2% low-fat milk or skim milk, whole milk, etc.

Shipping And Distribution

Special stainless steel insulated refrigerated storage tanks are required to transport the milk after its production. Most transport trucks use 7,000-8,000 gallon tanks. The rest are straight chassis tank trucks, usually able to transport 5,000 to 6,000 gallons. The milk is normally collected from the farms every 24-48 hours.

It is then loaded onto the truck for transport to its destination areas. Milk transport services have the responsibility of ensuring the shipments arrive safely to their destinations. There a number of milk transport services in the United States and in other countries around the world.

Once tested and put on the trucks it is then shipped to it’s specified grocery stores, refrigerated and stored until sold. The process of production is not that complex and is pretty straight forward. And milk transport services ensure families around the world can enjoy the nutritious benefits and delicious flavor of milk worldwide.

With three generations into the freight, dairy and food-grade transportation industry, a company like FreightLinxs can help you transport your milk from one place to another with utmost safety.

A Freight Broker is a company that helps its customers find a freight carrier that will be able to provide on time and on budget freight services.

Technology allows more transparency today than ever before in history. It only makes sense that we use that technology to better service the freight community. Without profitability, no company survives. Therefore, the purpose is simple; optimize carriers loaded miles so the shipper can benefit with more competitive freight rates. We can only move forward by adding value to both sides of the equation. The shipper and carrier combined.